What We Believe

Passion in what we do is key to excellence.

For over thirty years, our steadfast commitment to fostering partnerships, enhancing manufacturing excellence, advancing bike development, ensuring supply chain agility, and upholding sustainability initiatives has been our hallmark. We firmly believe that true beauty lies in the smallest of details.

Initially, we had limited knowledge about how to address the challenges of our bicycle manufacturing processes. But our lack of preconceived notions turned out to be our greatest advantage. We are consulting with various experts, we repeatedly encountered responses like, "This is how it's always been done" or "That's the established method." Fueled by our passion and spirit, we chose to trust our own intuition and break the tradition. In our workshop, we embarked on a journey of experimentation and innovation.

Founder of Insera Sena

The place where it all starts

Born in Sidoarjo, Indonesia, in 1989, we foster innovative ideas and meticulously engineer processes, ensuring quality control at every stage of production. From hand-welded frames to painting lines and assembly facilities. Collaborating with our global partners, we showcase flagship products while also prioritizing the resilience and sustainability of our supply chain.

From a 6-hectare 'kitchen' with a dedicated team, we seamlessly blend craftsmanship, expertise, and advanced technology to manufacture nearly a million bikes annually, cherished by millions worldwide.

Development Partnership: We support our customers even before the first molds are made

Beyond merely manufacturing bicycles, our partnership offers a holistic approach that extends far beyond production. Drawing upon insights and resources gleaned from over 20 brands, we are uniquely positioned to support our customers comprehensively. With a single point-of-contact, we streamline communication channels, ensuring a seamless and efficient experience for all parties involved.

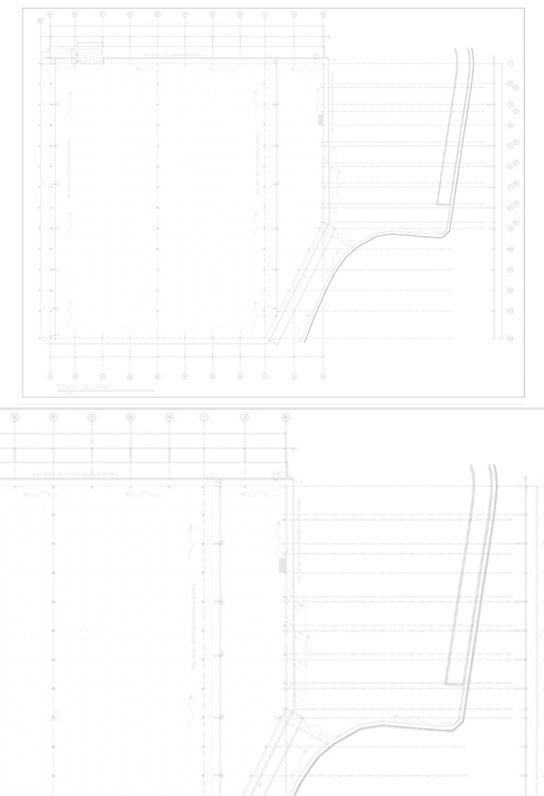

Design, Specs, and Engineering

Dedicated team to develop frames, artwork, and specifications

Reliability

and Packaging

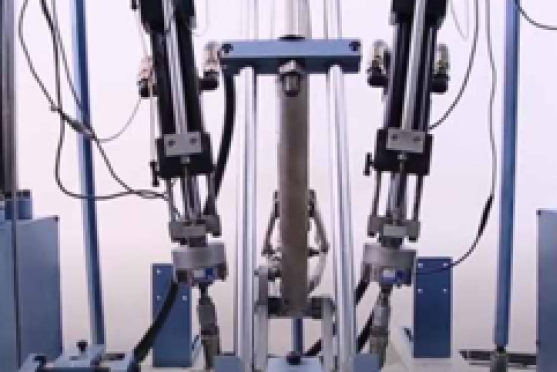

Reliability analysis by DFMEA (Design Failure Mode and Effects Analysis) Process and on-site testing labs

Manufacturing Process

A streamlined and detail-oriented manufacturing process

Developing Marketing Collaterals

Professional product photography studio

Manufacturing Excellence: Our strength lies in our orientation to detail

Our world-class facility boasts cutting-edge technologies designed for precision and efficiency. With a single governing system in place, we ensure complete visibility throughout our operations. Our stringent quality-control process guarantees consistency and customer satisfaction, reinforcing our commitment to excellence at every stage of production.

Supply Chain Resilience: We empower our customers to anticipate and adjust to market dynamics

In times of shortages, we leverage buffer inventory to expedite rush orders, particularly during high-demand periods such as the COVID boom. Our global collaborations with vendors and customers provide insights into market trends, facilitating efficient demand planning. This proactive approach not only reduces cycle times but also enhances agility and responsiveness to market changes, allowing for prompt adjustments/ supply developments to meet global demands.

Moreover, we offer customers the option to delay shipping and logistics expenses by serving as their local warehouse facility for excess inventory.

Sustainability Initiatives: Being a force of good for the community

At the heart of our operations lies a deep-rooted dedication to forging a greener path. We believe that even small steps can pave the way for significant change, and that's why we value every endeavor no matter how incremental it may seem.

Our belief extends to various initiatives aimed at strengthening the very foundation of sustainability. From collaborating with leading institutions and suppliers to create shared standards for a sustainable supply chain, adopting biodegradable and eco-friendly resources, and nurturing our local communities. Our journey toward a greener horizon is propelled by our collective determination to make a positive impact on the planet we all call home.

Today, we not only seek out the most skilled specialists but also frequently welcome career changers and self-taught individuals into our ranks. We don't confine ourselves to established product traditions; rather, our willingness to experiment with diverse material combinations has the power to astonish even the most seasoned craftsmen.

Chairman of Insera Sena

Working with Athletes and Ambassadors

Welcome to our vibrant world of cycling and meet our exceptional riders and cycling teams. We are fueled by a passion for cycling and a drive to achieve greatness on two wheels. We all believe cycling changes lives; so, equipped with unwavering dedication and skills, we pedal towards triumph, celebrate the exhilaration of cycling together, and continue inspiring the world.

Ensuring our designed value chain sustainability with annual

assessment by trusted institutions